Note from Sean:

Today’s guest post is from Fred Perrotta of Tortuga Backpacks. I was really excited for Fred to share today because he does something similar, but completely different to what I often write about here on Location 180.

He travels the world, he runs a business, he does the things he wants, but he does it all with a physical product business. This brings its own set of challenges and rewards – and it’s a perfectly viable option for other people looking to build a business that allows them to become a Location Rebel.

For it to work however, you’ll need to plan ahead and follow the advice Fred shares.

Take it away, Fred…

Oh, and that view above was from his “office” while he was in Mexico.

—

I’ve run my company, Tortuga Backpacks, from San Francisco, Guangzhou, Hong Kong, Ensenada, London, and more.

Right now I’m running the company from Thailand before heading back to Guangzhou then to New York City.

Running a freelance writing or software business remotely is easier. Everything can be done online. A physical product business will require, or at least greatly benefit from, some in-person work.

Assuming your goal is to be location independent, why would you possibly start a physical product business? Because the opportunities are huge and the barriers to entry (for your competitors) are real. Plus, you’ll have the added satisfaction of making something that you can touch and feel and show to other people.

Having previously worked in online advertising, I appreciate having a physical object to show for my work.

In the service businesses popular with digital nomads, markets can be crowded and you’ll have to contend with other low priced competitors. Instead of fighting against people from countries with lower costs, use geo-arbitrage to your advantage by manufacturing in China and selling to the West. For instance, you can buy your product with renminbi (Chinese currency) and sell it for dollars.

Manufacturing in China, or anywhere else, doesn’t require you to live there permanently. You can still travel or live where you please with the right systems in place.

In this post, I’ll outline the systems that we use at Tortuga Backpacks to run a location-independent business with a distributed team. The advice will be as much about how to run your business remotely as when you need to be on-site.

Product Design and Sampling

Tools for Working Remotely: Email, Skype, Google Docs, Photoshop or Skitch, Illustrator or CAD software

In-Person Work: Evaluating and testing samples

To create physical products, you need to see, feel, and test your product in person.

Sketching and low-fi prototypes are great but will only get you so far. Eventually, you need a physical sample of your product to evaluate it.

We work with an industrial designer to create new products. The initial phases of research, ideation, and design can be done remotely via email and Skype.

We start by creating a “working doc” that we share with our designer.

This Google Doc defines the mission of the product, the parameters (size, weight, price target), and the competitive landscape. We’ve made the competitive matrix for our daypack public so that you can see a real world example. When the working doc is ready, we review it with our designer over Skype, and he adds his own research and feedback.

The next stage is to create, review, and refine sketches.

Our designer presents a handful of different options, we pick and choose what we like, then he refines the designs.

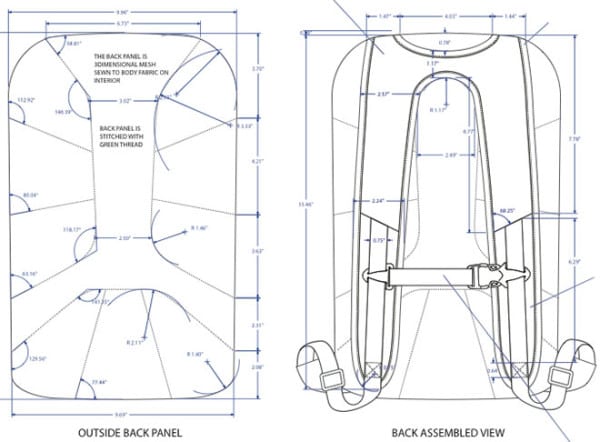

After we hone the concept, the designer turns the sketches into a tech pack for the factory. A tech pack is like a blueprint for soft goods. This design document, made in Adobe Illustrator and shared as a PDF, illustrates the product from every side, notes measurements and angles, and lists the materials and hardware to be used.

Other types of products, like hardware, will need to be designed in AutoCAD or another computer-aided design tool.

Sample image from the tech pack for the Tortuga Daypack

You then send the tech pack to one or more suppliers to have samples made. We’ll discuss how to find a supplier in the next section on sourcing.

The sampling and prototyping process requires you to get your hands on your product. You can rely on your designer for the first round or two of prototypes when you’re still fixing basic construction problems. We often have the first sample of a new product sent directly to our designer so that he can correct any glaring errors before we start testing it and nitpicking the smaller details.

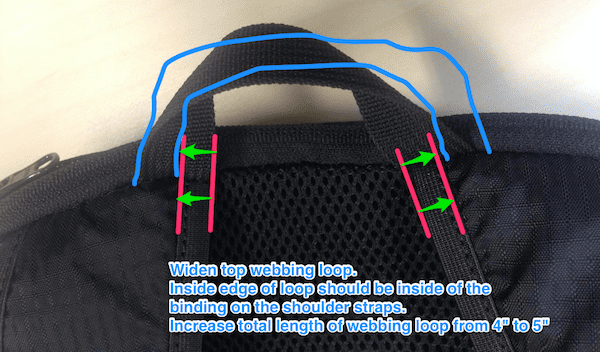

If you manufacture in China, communication will be a challenge. Work with suppliers that are responsive and can communicate clearly by email or over Skype. Most importantly, communicate as much product feedback as possible visually. My Photoshop skills are below par, so I use Skitch for making notes.

This is an actual note that I sent to our supplier

I take pictures with my iPhone, use Dropbox’s Camera Upload to get them onto my computer, then make notes in Skitch.

Draw arrows to communicate what you want. Add text to explain it. Send links to other products that look or work similarly to what you want.

We mail other products and fabric samples directly to our suppliers for their reference. Follow the old Hollywood advice: show, don’t tell.

Factories are great at copying – and I don’t mean that as an insult. The more examples you can give them, the better their samples will be.

Send your notes by email and ask your supplier’s rep to explain the changes back to you. Don’t ask yes/no questions. Don’t ask, “Do you understand?” Ask the rep to say what needs to be changed to ensure that he can communicate those changes to the sample maker at the factory. The feedback is being passed from you to the rep to the sample maker. Don’t leave any room for interpretation.

You can give feedback remotely but you’ll still need to see your products in person.

The good news is that you can have samples shipped anywhere in the world. The bad news is that some countries that location independent bootstrappers favor, like Vietnam, are exporters and aren’t keen on your importing products.

Have your shipments are labeled as “samples” and proceed at your own risk. During this process, you’re better off being in the country where you’re manufacturing or in a country that regularly imports from your products’ country of origin to minimize shipping problems.

Shipping from China to the US is expensive, but I always get the packages. After a few rounds of revisions, you will have a “production sample” that’s ready for mass production.

Before you can get samples, you’ll need to find a reputable supplier or two. Let’s tackle that problem next.

Sourcing

Tools for Working Remotely: Alibaba, Enter China, sourcing agent

In-Person Work: Canton Fair, Factory visit

Bottom line? Sourcing suppliers is hard.

You don’t just need to find one supplier who can make your product, you need to find a few, compare their quality and prices, and choose a partner that you can work with for years to come. Having strong supplier relationships will save you a lot of headaches.

Many prospective entrepreneurs start their search on Alibaba, the directory of Chinese factories. For more on how you can start working with Alibaba, check out this post.

With Alibaba, you can start the sourcing process remotely. Alibaba listings show the supplier’s products and facilities. Make sure to filter the results by ‘Gold Suppliers’ with ‘Onsite Checks.’ As with any supplier, ask for references from past customers and have samples sent to you for review.

Alibaba’s search results for backpack

Alternatively, you can work with a sourcing agent whose job is to connect companies with vetted suppliers. We’ve worked with an agent for the last few years whom we met through a mutual friend.

Whether you’re looking for a sourcing agent or a supplier, referrals are always the best option. Having someone trustworthy working as your “boots on the ground” will help you stay remote without neglecting the important work of sourcing good suppliers. Joining Enter China helped me expand my network of people working in China, including sourcing agents.

When you have a shortlist of suppliers, you can meet them in person at the Canton Fair or by arranging a factory visit. Some things should be done in person. In person? Yes, in person. More on this in the last section on ‘When to Be There.’ You can go through most of the process remotely then use your in-person time judiciously to get projects across the line.

Join over 40,000 people who have taken our 6 part freelance writing course. Sign up below and let’s do this together.

By entering your email address you agree to receive emails from Location Rebel. We'll respect your privacy and you can unsubscribe at any time.

Production and Quality Control

Tools for Working Remotely: Email, WeChat, QC agent

In-Person Work: QC check of first production run

Similar to what we talked about with a sourcing agent, a good quality control (QC) agent will make your life easier and let you spend your time running your business from wherever you want, not sitting in a factory.

Overseeing production is good to do at the outset to ensure quality and to set a precedent with your supplier.

However, ultimately, you cannot be the person overseeing manufacturing for every production run. QC is location dependent. Are you a QC agent or a CEO? Good. Do your job.

Ryan from Original Grain said the following about QC in his post,

I would suggest for those who are not able to either go visit the factory at all or do quality control, hire out someone to do this for them. Absolutely do not try and do this from your home country and outsource with no help from someone on the ground. And I strongly advise you make a visit to see your factory at some point.

Yes! Ideally, you can do a QC check for the first production run yourself. Then you can hire help. You will need help to run your business remotely. Hiring makes the process more expensive, but you aren’t just paying for QC, you’re buying your freedom.

Please do QC before your cargo leaves the factory.

Once it leaves, you assume control of the bill of lading and are legally responsible for it. Any defects you find after your cargo leaves the factory are your responsibility. The farther your product gets from the source, the more expensive problems are to fix.

A basic QC check in China will only cost $150–300 for the day. A few hundred dollars is cheap for the peace of mind it provides and the more expensive problems that it prevents. For that fee, your QC agent checks your order for defects, confirms carton and pallet labeling, and presents you with a report on any major or minor issues.

Our QC agent sends us reports via email and pictures via WeChat, a popular messaging app in China. WeChat is a convenient way to communicate in real-time, without the lag of email, when your QC agent is at the factory.

As you grow as a company, you can hire a part-time or full-time QC agent or contract with a larger firm, which will handle even more of the production process.

We haven’t taken this step yet, but I’ve spoken to agents who handle all communication with your supplier and fly out to oversee production and QC. These firms charge 8–15% of your invoice total and have significant minimum fees.

Logistics, Warehousing, and Shipping

Tools for Working Remotely: Shopify, freight forwarder, third-party logistics service

In-Person Work: None!

If you’ve ever been inside a post office, you know how fun shipping is. Warehousing and shipping your product is a perfect task to outsource to a third-party with expertise and good software integrations. I mention the latter because smaller fulfillment services are often low-tech. You need a company that can integrate with your ecommerce store to avoid the manual work of using spreadsheets and to minimize human error.

Ecommerce platforms like Shopify, which we use, integrate with many third-party logistics (3PL) services. They may cost more than a lower-tech option, but you’re paying for convenience and simplicity.

First, you need to get your product from your supplier to the warehouse. Since we manufacture in China, we use a freight forwarder.

Our supplier’s prices are “freight on board” (FOB) meaning that they will load the freight at a specific port. If you’re manufacturing in Southeastern China, get a price quoted as FOB Shenzhen or FOB Hong Kong.

You are responsible for everything between when your supplier loads the cargo onto the ship to when that cargo is accepted by your warehouse. We work with a freight forwarder that accepts the cargo from the supplier, ocean freights it to the US, gets it through customs, then trucks it to the warehouse.

The freight forwarder invoices us after the cargo clears customs in the US. Orders with smaller customs charges may not be invoiced until the cargo has been delivered to the warehouse.

If possible, track down a reference so that you’re working with a reliable freight forwarder. I recently found Flexport and Kontainers, two tech-focused freight forwarders. I haven’t used either one yet but will get a quote from them for our next shipment.

Having additional tracking and a web-based interface may be worth a small price difference. The freight forwarders that I’ve worked with use the phone, email, and spreadsheets, which leads to extra back-and-forth that I prefer to avoid.

For storage and fulfillment, we’ve used Fulfillment by Amazon (FBA) and Shipwire. I’ve also heard good feedback about Mochila which was started by ex-Amazon FBA employees. For more on working with Amazon FBA, take a look at this post.

Price is always important when choosing a 3PL, but you should also look for integration with your ecommerce software to make the process as easy as possible. You want customers to find your site, place an order, and receive your product without you doing anything.

Depending on your business, you should also think about custom packaging and inserts, how the 3PL handles returns, where it’s located, and international shipping. Work with a warehouse near your customers to minimize shipping times and costs.

When To Be There

If your goal is to be location independent, you’ll need to use software, employees, and third-party companies to automate as much as possible and to handle some of the necessary in-person work.

You won’t nail all of these systems right off the bat.

We’ve switched 3PL services once and freight forwarders twice. We’re currently looking for a supplier for a new product line. We’ve worked with a handful of VAs and two different industrial engineers.

No system is perfect. Stuff happens. You will change and adapt as necessary.

The ability to adapt and to survive is crucial to being an entrepreneur.

Use your in-person time to build stronger working relationships than you could over Skype.

As you narrow your search to one or two suppliers, spend the money to visit them in person. Travel is expensive, but it’s cheaper than botched orders or delayed shipments because you chose the wrong supplier.

With Alibaba and Kickstarter, people think they can start a physical product business without any real time or financial investment. Suppliers are getting more and more inquiries, mostly from uncommitted wantrepreneurs.

To convince a supplier that you’re serious, show up. Tell them you’re coming and schedule a visit. Get a visa. Right now, you can get a Chinese 10-year visa.

You’ll have a great time, you’ll learn a ton, and you’ll start to build real relationships with your suppliers. Your supplier will pick you up at your hotel or at the train station, take you to the factory, show you around, and buy you lunch or dinner. You just have to show your commitment, be polite, and get to know everyone.

Showing up in person will help you work your way up the food chain at the factory. You’ll go from emailing with a sales rep to having tea with the “laoban” (boss).

Who do you think will get better service: the person cold emailing through Alibaba or the person who broke bread with the boss?

Running a physical product business remotely isn’t easy, but it isn’t rocket science. Put in the work, and you’ll reap the rewards. Don’t take dumb risks to save a few dollars or because you don’t want to be somewhere in person. Think long-term.

The best times to show up in person are when vetting new suppliers, for initial QC checks, for periodic relationship-building visits, and for the Canton Fair. I try to do more than one of these per trip. The Canton Fair is also a great time to network with other entrepreneurs and people working in China.

We’ve been sourcing from China for the last three years, and I only visit twice per year. Twice per year probably sounds infrequent, but I’ve spent the last 5+ years building our system and learning everything through trial and error. Everything.

Start slowly.

Ask for referrals but earn them first.

I get a lot of emails from total strangers asking for a referral to our factory. I’m happy to help, which is why I’m writing this post, but I wouldn’t jeopardize our supplier relationships for someone I didn’t know.

Implement one system at a time then stress test that system. To be successful, you have to extricate yourself from most tasks so that you can focus on the most important ones that only you can do.

When things are running smoothly, go offline for a few days. Then for a week. Gradually work your way to being fully, or at least primarily, location independent.

Building a system that grants you freedom (and income) is the definition of success.

Sean Ogle

Sean Ogle is the Founder of Location Rebel where he has spent the last 12+ years teaching people how to build online businesses that give them the freedom to do more of the things they like to do in life. When he's not in the coffee shops of Portland, or the beaches of Bali, he's probably sneaking into some other high-class establishment where he most certainly doesn't belong.Join over 40,000 people who have taken our 6 part freelance writing course. Sign up below and let’s do this together.

By entering your email address you agree to receive emails from Location Rebel. We'll respect your privacy and you can unsubscribe at any time.

I AM SO LUCKY I FOUND THIS BLOG A FEW MONTHS AGO! YOU ALWAYS WRITE ABOUT THE SUBJECTS I AM LOOKING FOR! :)) THANK YOU!! (Especially this post made my day, or entire week maybe)

Thanks, Ayca. Let me know if you have any follow-up questions in the comments or on Twitter.

Thank you Fred, I will contact you.

Great post ! I would have loved to see all links open in new tab though.

One of the best posts here, ever.

Wow. That is high praise, Justin. Thank you!

Awesome post. This is a business model I have often thought about, really cool to read about how you make it work. Thanks for putting this together!

..and now I think I know what backpack I am buying next!

Two birds with one stone 🙂 Awesome.

Awesome post!

I’ve been thinking of doing something along these lines, but always been too scared of all the uncertainties . This post really helped shine some light on the whole process though!

Wow, I never knew that it’s possible to run an import-export business like what was described here. We’ve been importing from Guangzhou for decades but have never tried to do it remotely. As much as possible, we’re always present at the transaction. What shipping company are you using? Have you tried EMS? For us, they’re fast, cheap and secure. And, yeah, the China Exhibition Fair is great. Bring plenty of business cards if going there.

Hey Manuel,

I’m not familiar with EMS. We haven’t used them. Are they for freight forwarding from GZ ? Or for shipping small items?

Fred,

EMS mostly are for small packages. They’re a lot cheaper than their American counterparts. Alibaba shippers use them all the time. They have branches all over China and at the Hong Kong post office. They’re great for sending samples but if you’re doing freight containers, I don’t know if they have it. But they’re fast, only 3 days from Guangzhou to Canada.

Manuel

Brilliant article Fred! Thanks so much for going into such detail about your experiences. I’m launching a non-profit from the UK that will depend on developing strong relationships with Chinese manufacturers if we’re to achieve our $10 monthly subscription target. Although I’ve already started the process of communicating with suitable partners, there is plenty I’ve learnt from you here that will help me going forward. I’ve also enjoyed reading your personal blog.

By the way, my wife is a Perrotta from Napoli (Italy). There aren’t many about. Is that where your family originate from?

Julian

That was a great article. It had many different gems that are so important to remember, but can easily be forgotten or overlooked. If people take the time, and really take action on the things you said, they will well on their way to living the life they want. Thanks for taking the time to write it!

Hey Fred,

This was a really great post. I’ve used 180 to start a freelance writing business that I run from abroad now. This site has really been a great help. I hope that you are still answering questions because I have a few if you don’t mind!

Do you sell to people internationally? If so, where did you register this business?

From what I have read, fulfillment centers are very expensive. How did you manage to afford one when just starting out?

Can you give me a rough estimate of the capital that you had when starting out on this venture so I can better gauge where I stand?

Thanks a lot!

Hi Kevin,

Yes, we sell internationally. We’re registered in the US.

Most 3PLs (fulfillment services) charge a monthly fee by storage space volume + shipping and handling fees on each order. Minimize one or both if you’re trying to save money.

We had a long, drawn-out process when starting 6 years ago. I don’t know the total numbers nor would they necessarily be relevant.

-Fred

Shipwire is a piece or sh*t. Maybe works for you but people should be aware and read all the bad reputation they have everywhere.

Fred,

What an amazingly, in-depth article! It’s quite rare to find articles focused on entrepreneurs selling physical products, especially one loaded with so much information!! As a physical product entrepreneur, and electronics design engineer that focuses on helping entrepreneurs, it’s really nice to see such a detailed article on all of the logistics required for selling physical products.

Nice job Fred!

Best wishes,

John Teel

Predictable Designs

Thanks for the great article! I am just starting a business very similar to this. I have already gone through most of what you have outlined here and am about to travel back to China in a month for the first run QC. My product will not only be sold online but at any number of retail garden stores and hydroponic stores. It it still viable to be location independent when I need to go and make these sales to stores to get on their shelves? My plan was to first have my own warehouse while I form the relationships with stores and then find a 3PL after I get on their shelves and am carried by a distributor. Is there a better way of doing this? Any advice would be much appreciated! Thanks you for your help!

All the best,

Zach

I’m so curious about how you decided on producing a backpack. It seems like it would be such a challenge going up against established backpack companies that have saturated the market. Did you do lots of research before hand or were you set on making a backpack from the beginning?